I-DC brushless roller kagesi

-

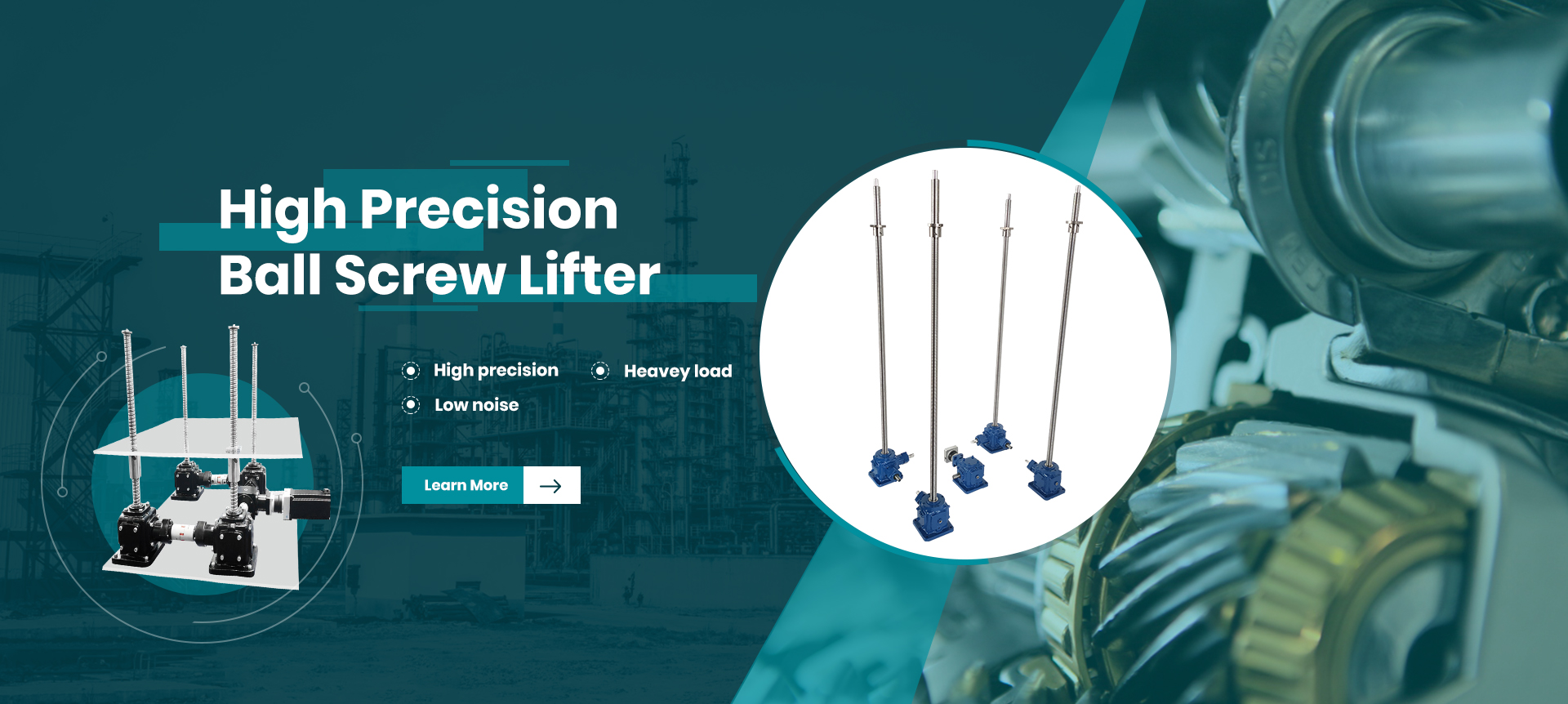

I-BLD DC i-brushless roller kagesi

Lolu hlobo lwe-drum motor lungafakwa endaweni elinganiselwe futhi luhlangabezane nemfuneko ye-torque.Isebenzisa amagiya ensimbi agayiwe kanye nesakhiwo sokudlulisa iplanethi, ithembekile, ayilungiswa futhi ivuselela uwoyela, iyonga isikhala.Ingasetshenziswa emikhakheni eminingi:

Umthengisi wesitolo esikhulu

Imishini yokupakisha Isihambisi sebhande

Ulayini wokuhambisa ibhandeIzimpawu ze-BL50 Ze-Drum Motor

Igobolondo lesigubhu

Impahla yegobolondo lesigubhu elijwayelekile iyinsimbi ethambile • Igobolondo le-garde yokudla liyinsimbi engagqwali engama-304 • Igiya legiya elijwayelekile le-cylinder rolling mill - igiya • Ukunemba kwensimbi ye-alloy ephezulu, iqinisekisa ukudluliswa komsindo ophansi uma • Ukudluliselwa kwegiya leplanethi -

I-Double Groove O-belt Pulley Roller

1. I-O-belt pulley itholakala ekupheleni kwe-roller ehlukanisa indawo yokushayela kanye nendawo yokudlulisa ukugwema ukuphazamiseka phakathi kwe-O-belt kanye nezimpahla ezidlulisiwe.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini yesiphetho sokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli namanzi afafaziwe.

4. Ngenxa yokuthi ayikho i-grooving ye-tube, ithubhu ngeke ibe nokuhlanekezela futhi i-roller izohamba kahle kakhulu.

5. Ukucushwa okujwayelekile nge-anti-static design surface impedance≤106Ω.

6. Ibanga lokushisa: -5℃ ~ +40℃.Sicela usithinte uma umswakama ungaphandle kwalo mkhakha. -

I-Poly-vee Conveyor Roller

1. I-poly-vee pulley itholakala ekupheleni kwe-roller ehlukanisa indawo yokushayela kanye nendawo yokudlulisa okwenza ukuhambisa kube bushelelezi, isivinini esikhulu nomsindo ophansi.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini yesiphetho sokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli namanzi afafaziwe.

4. ISO9982 PJ uchungechunge poly-vee.Isamba semigodi engu-9 ku-2.34mm pitch.

5. Ubude obuhlukahlukene bebhande le-PJ buyatholakala ukuze buhambisane nephimbo elihlukile lamarola.

6. Ifanele izicelo zejubane eliphezulu.Isivinini esikhulu siyahlukahluka ngobude berola nobubanzi.Isivinini esiphezulu sifika ku-2~3m/s.

7. Ukucushwa okujwayelekile nge-anti-static design surface impedance≤106Ω.

8. Ibanga lokushisa: -5℃ ~ +40℃.

Sicela usithinte uma umswakama ungaphandle kwalo mkhakha. -

I-Double Grooved O-belt Conveyor

1. Uma kuqhathaniswa ne-chain drive, i-O-belt drive inezinzuzo zomsindo ophansi kanye nesivinini esikhulu.Isetshenziswa kakhulu kwikhathoni yomsebenzi okhanyayo/omaphakathi

ukudlulisa.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini yesiphetho sokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli namanzi afafaziwe.

4. Isikhundla se-grooves singenziwa ngokwezifiso.

5. Ukucushwa okujwayelekile nge-anti-static design surface impedance≤106Ω.

6. Ibanga lokushisa: -5℃ ~ +40℃.

Sicela usithinte uma umswakama ungaphandle kwalo mkhakha. -

Isikhathi sebhande le-pulley conveyor roller

1. Isakhiwo esihlangene, ukungezwani kwamahhala, umklamo olula.

2. Iphrofayili yezinyo le-T5 ilungele ukuhanjiswa kwe-roller, indawo yonke ephakeme.

3. Ukuma okunembile, ukuhlanganisa ne-MDR kungafanisa ukusetshenziswa kwesigaba sokufakelwa.

4. Hlanganisa ne-PU Timing belt ingafanisa ukusetshenziswa kwekamelo elihlanzekile kanye nezinye imvelo enokhahlo.

5. Ukuzigcoba ngokwakho futhi akunasondlo. -

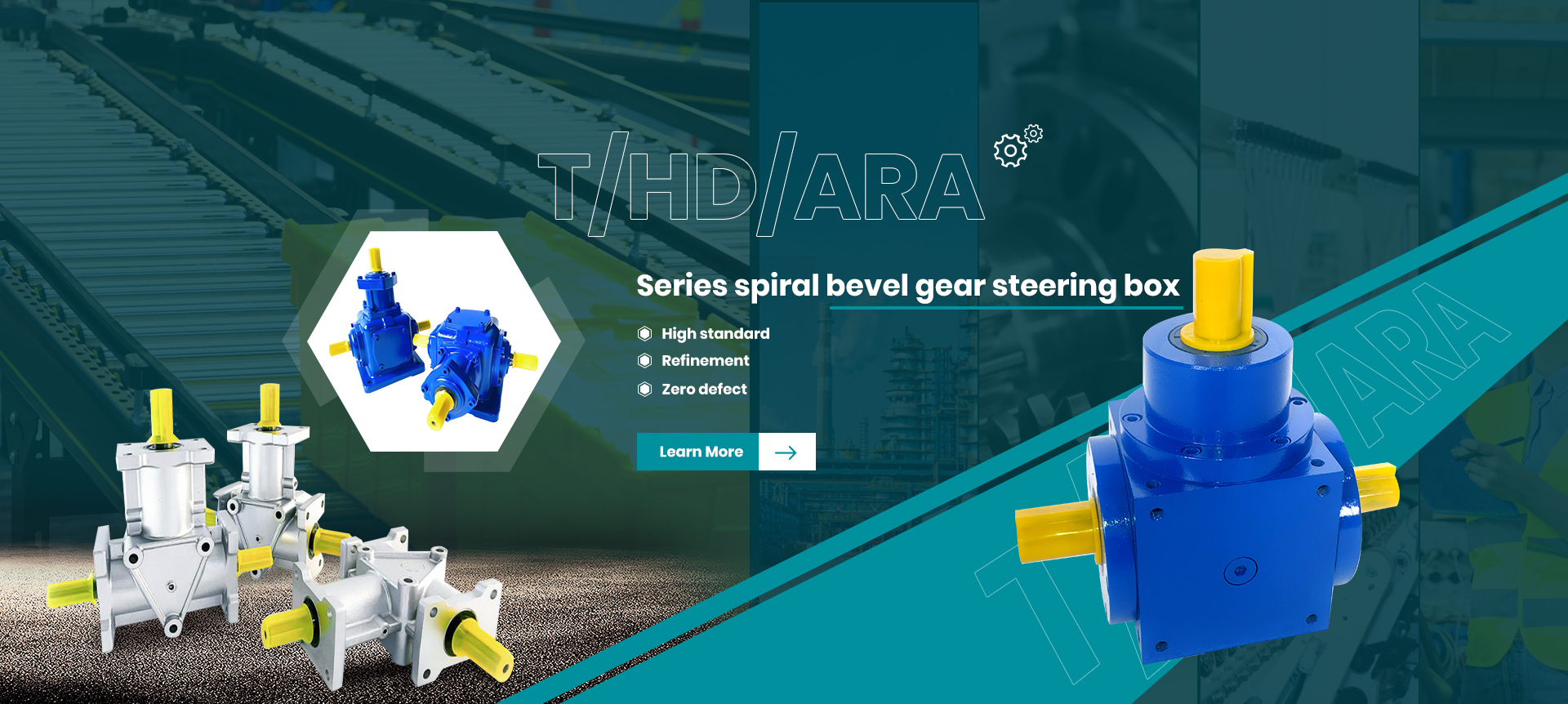

I-DC brushless roller kagesi

Lolu hlobo lwe-drum motor lungafakwa endaweni elinganiselwe futhi luhlangabezane nemfuneko ye-torque.Isebenzisa amagiya ensimbi agayiwe kanye nesakhiwo sokudlulisa iplanethi, ithembekile, ayilungiswa futhi ivuselela uwoyela, iyonga isikhala.Ingasetshenziswa emikhakheni eminingi:

Umthengisi wesitolo esikhulu

Imishini yokupakisha Isihambisi sebhande

Ulayini wokuhambisa ibhandeBLD 60 Izimpawu Ze Drum Motor

Igobolondo lesigubhu

Impahla yegobolondo lesigubhu elijwayelekile iyinsimbi ethambile • Igobolondo le-garde yokudla liyinsimbi engagqwali engama-304 • Igiya legiya elijwayelekile le-cylinder rolling mill - igiya • Ukunemba kwensimbi ye-alloy ephezulu, iqinisekisa ukudluliswa komsindo ophansi uma • Ukudluliselwa kwegiya leplanethi -

I-Double Sprocket Roller enezindlu ezine-polymer

1. Ukushisela i-sprocket yensimbi epayipini lensimbi kuyinikeza amandla okudlulisa i-torque ephezulu futhi ihlangabezane nezidingo zokuthutha umsebenzi osindayo.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini ye-cap yokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli kanye ne-splashed water roller.

4. Ibanga lokushisa: -5℃ ~ +40℃.

Umswakamo uyatholakala ≥ 30%

Sicela usithinte uma umswakama ungaphandle kwalo mkhakha.I-roller conveyor iklanywe njenge-roller trough trough roller yokuthutha impahla eqhubekayo, ngisho noma inkulu noma isindayo.Amarola kagesi angaba uthayela, insimbi engagqwali noma embozwe.I-roller ingenziwa nge-friction roller ukwenza lula ukugcinwa kokupakisha.