Imikhiqizo

-

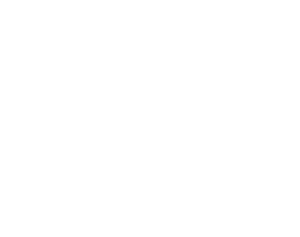

Inkundla yokuxhuma i-Screw elevator

Inkundla yokuxhuma ye-screw lifter iyiyunithi yokukhipha ukunyakaza kwe-mechatronic ehlanganisa ngobuchule injini, isinciphisi, igiya lokuqondisa kanye nesiphakamisi sesikulufu ngokuhlanganisa, i-transmission shaft nokunye.Ingabona ukusetshenziswa kokuxhumanisa kwezikulufu eziningi, ihlangabezane nezidingo zokuphakamisa okuningi okuzinzile, okuvumelanayo nokuphindaphindayo, futhi ibone nomnyakazo ogumbuqelayo.Ngakho-ke, ingathatha indawo yokudluliselwa kwe-hydraulic kanye ne-pneumatic yendabuko izikhathi eziningi.Le yunithi yokunyakaza esekelwe ku-worm gear screw lifti inikeza isikhala esisebenzayo esibanzi konjiniyela ukuze bathuthukise imikhiqizo enkathini yedijithali.Isetshenziswa kabanzi kumandla elanga, i-metallurgy, ukudla, ukongiwa kwamanzi nezinye izimboni.

-

KM uchungechunge lwe-Hypoid gear reducer

I-KM series hypoid gear reducer isizukulwane esisha semikhiqizo esebenzayo eyakhiwe ngokuzimela inkampani yethu.Ihlanganisa ubuchwepheshe obuthuthukisiwe ekhaya naphesheya futhi inezici ezilandelayo eziyinhloko:

1. Ukuhanjiswa kwegiya le-Hypoid kuyemukelwa, ngesilinganiso esikhulu sokudlulisela

2. I-torque enkulu yokukhipha, ukusebenza kahle kokudlulisa, ukonga amandla nokuvikelwa kwemvelo

3. Ikhwalithi ephezulu ye-aluminium alloy casting, isisindo esilula, akukho ukugqwala

4. Ukudluliselwa okuzinzile nomsindo ophansi, ofanele umsebenzi oqhubekayo wesikhathi eside endaweni enzima

5. Kuhle futhi kuqinile, umthamo omncane

6. Ingafakwa kuzo zonke izinhlangothi, isetshenziswa kabanzi futhi kulula ukuyisebenzisa

7. Ubukhulu bokufakwa kwe-KM series reducer buhambisana ngokugcwele ne-nmrw series worm gear reducer

8. Inhlanganisela ye-Modular, engahlanganiswa ngezindlela ezihlukahlukene ukuhlangabezana nezidingo zezimo ezihlukahlukene zokudlulisela -

Ukudlulisa Okuguquguqukayo kwe-Mb okuqhubekayo

Isakhiwo kanye nomgomo wokusebenza

1. I-Planetary cone-disk variator (bona umdwebo)

Womabili amasondo elanga ane-conicity(10) kanye ne-press-plate (11) aminyaniswe iqoqo lama-butterfly springs (12) kanye ne-input shaft (24) ixhunywe ne-sloar-wheel ngokhiye ukuze kwakheke okokufaka okuminyene. idivayisi.Iqembu lamasondo eplanethi anobumbano (7), nohlangothi lwawo lwangaphakathi olubambene phakathi kwesondo elibambezelekile lelanga kanye ne-pres-plate kanye nohlangothi lwangaphandle phakathi kweringi engaguquki ene-conicity (9) nekhamera elawula isivinini (6) ), lapho idivayisi yokufaka inyakaza, igingqika kanye neringi egxilile ngenxa yakho kokubili indandatho engaguquki nekhamera elawula isivinini engashintshile ngaphandle kokunyakaza futhi wenze inguquko izungeze i-shaft yokufaka ukuze ushayele kokubili i-planetary rack (2) kanye ne-output shaft (1) ukuze isebenze. ngokusebenzisa i-planetary-wheel shaft kanye ne-slide block bearing (5).Ukuze ulawule isivinini, vula isondo lesandla, elishayela isikulufu sokulawula isivinini ukuze ikhamera yangaphezulu igijime ngokuqhathaniswa ukuze ikhiqize i-axial displacement futhi ngaleyo ndlela uguqule ngokulinganayo isikhala phakathi kwekhamera elawula isivinini kanye nendandatho engaguquki futhi, ekugcineni, ushintshe irediyasi esebenzayo. endaweni eshayisanayo yekhamera phakathi kwe-planetqry-wheel ne-solar-wheel naphakathi kwe-press-rack nendandatho engaguquki ukuze kubonakale ukuhlukahluka kwesivinini esingenasinyathelo. -

I-WB Series ye-micro cycloidal speed reducer

Ukubuka konke komkhiqizo:

I-WB series reducer iwuhlobo lwemishini eyehlayo ngokuya ngesimiso sokudluliswa kweplanethi enomehluko omncane wamazinyo kanye ne-cycloid yenaliti yezinyo zokuxhuma.Umshini uhlukaniswe waba yi-horizontal, mpo, shaft kabili kanye nokuxhumana okuqondile.Kuyimishini evamile kwezensimbi, izimayini, ezokwakha, imboni yamakhemikhali, izindwangu, imboni yokukhanya nezinye izimboni.

-

CV CH ukunemba igiya motor reducer

Izici zokusebenza:

1. Isivinini sokuphuma: 460 R / min ~ 460 R / min

2. I-torque yokuphumayo: kufika ku-1500N m

3. Amandla emoto: 0.075kw ~ 3.7KW

4. Ifomu lokufaka: uhlobo lwe-h-foot, uhlobo lwe-v-flange -

Uchungechunge lwe-P olunembayo lokuncishiswa kweplanethi

Uchungechunge lwe-P olunembayo lokuncishiswa kweplanethi, i-servo planetary reducer elinye igama lokunciphisa amaplanethi embonini.Isakhiwo sayo esihamba phambili sithi: igiya leplanethi, igiya lelanga kanye negiya elingaphakathi.Uma kuqhathaniswa nezinye izinciphisi, isinciphisi seplanethi ye-servo sinezici zokuqina okuphezulu, ukunemba okuphezulu (ngaphakathi kwephuzu elingu-1 esigabeni esisodwa), ukusebenza kahle kokudlulisela okuphezulu (97% - 98% esigabeni esisodwa), isilinganiso esiphezulu se-torque / umthamo, impilo yonke. ukugcinwa mahhala, njll. Iningi lazo lifakwe ku-steping motor kanye ne-servo motor ukunciphisa isivinini, ukwandisa i-torque kanye nokulinganisa inertia.Ngezizathu zesakhiwo, isilinganiso esincane sokwehla kwesiteji esisodwa si-3 futhi esiphezulu ngokuvamile asikho ngaphezu kwe-10.

-

I-BLD DC i-brushless roller kagesi

Lolu hlobo lwe-drum motor lungafakwa endaweni elinganiselwe futhi luhlangabezane nemfuneko ye-torque.Isebenzisa amagiya ensimbi agayiwe kanye nesakhiwo sokudlulisa iplanethi, ithembekile, ayilungiswa futhi ivuselela uwoyela, iyonga isikhala.Ingasetshenziswa emikhakheni eminingi:

Umthengisi wesitolo esikhulu

Imishini yokupakisha Isihambisi sebhande

Ulayini wokuhambisa ibhandeIzimpawu ze-BL50 Ze-Drum Motor

Igobolondo lesigubhu

Impahla yegobolondo lesigubhu elijwayelekile iyinsimbi ethambile • Igobolondo le-garde yokudla liyinsimbi engagqwali engama-304 • Igiya legiya elijwayelekile le-cylinder rolling mill - igiya • Ukunemba kwensimbi ye-alloy ephezulu, iqinisekisa ukudluliswa komsindo ophansi uma • Ukudluliselwa kwegiya leplanethi -

I-Double Groove O-belt Pulley Roller

1. I-O-belt pulley itholakala ekupheleni kwe-roller ehlukanisa indawo yokushayela kanye nendawo yokudlulisa ukugwema ukuphazamiseka phakathi kwe-O-belt kanye nezimpahla ezidlulisiwe.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini yesiphetho sokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli namanzi afafaziwe.

4. Ngenxa yokuthi ayikho i-grooving ye-tube, ithubhu ngeke ibe nokuhlanekezela futhi i-roller izohamba kahle kakhulu.

5. Ukucushwa okujwayelekile nge-anti-static design surface impedance≤106Ω.

6. Ibanga lokushisa: -5℃ ~ +40℃.Sicela usithinte uma umswakama ungaphandle kwalo mkhakha. -

I-Poly-vee Conveyor Roller

1. I-poly-vee pulley itholakala ekupheleni kwe-roller ehlukanisa indawo yokushayela kanye nendawo yokudlulisa okwenza ukuhambisa kube bushelelezi, isivinini esikhulu nomsindo ophansi.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini yesiphetho sokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli namanzi afafaziwe.

4. ISO9982 PJ uchungechunge poly-vee.Isamba semigodi engu-9 ku-2.34mm pitch.

5. Ubude obuhlukahlukene bebhande le-PJ buyatholakala ukuze buhambisane nephimbo elihlukile lamarola.

6. Ifanele izicelo zejubane eliphezulu.Isivinini esikhulu siyahlukahluka ngobude berola nobubanzi.Isivinini esiphezulu sifika ku-2~3m/s.

7. Ukucushwa okujwayelekile nge-anti-static design surface impedance≤106Ω.

8. Ibanga lokushisa: -5℃ ~ +40℃.

Sicela usithinte uma umswakama ungaphandle kwalo mkhakha. -

I-Double Grooved O-belt Conveyor

1. Uma kuqhathaniswa ne-chain drive, i-O-belt drive inezinzuzo zomsindo ophansi kanye nesivinini esikhulu.Isetshenziswa kakhulu kwikhathoni yomsebenzi okhanyayo/omaphakathi

ukudlulisa.

2. Isiphetho se-bearing end cap siqukethe ukunemba kwebhola, i-polymer housing kanye ne-end cap seal.Kuhlanganiswe kuhlinzeka nge-roller ekhangayo, ebushelelezi futhi egijima impela.

3. Idizayini yesiphetho sokugcina ivikela ama-bearings ngokunikeza ukumelana okuhle kakhulu nothuli namanzi afafaziwe.

4. Isikhundla se-grooves singenziwa ngokwezifiso.

5. Ukucushwa okujwayelekile nge-anti-static design surface impedance≤106Ω.

6. Ibanga lokushisa: -5℃ ~ +40℃.

Sicela usithinte uma umswakama ungaphandle kwalo mkhakha. -

Isikhathi sebhande le-pulley conveyor roller

1. Isakhiwo esihlangene, ukungezwani kwamahhala, umklamo olula.

2. Iphrofayili yezinyo le-T5 ilungele ukuhanjiswa kwe-roller, indawo yonke ephakeme.

3. Ukuma okunembile, ukuhlanganisa ne-MDR kungafanisa ukusetshenziswa kwesigaba sokufakelwa.

4. Hlanganisa ne-PU Timing belt ingafanisa ukusetshenziswa kwekamelo elihlanzekile kanye nezinye imvelo enokhahlo.

5. Ukuzigcoba ngokwakho futhi akunasondlo. -

I-DC brushless roller kagesi

Lolu hlobo lwe-drum motor lungafakwa endaweni elinganiselwe futhi luhlangabezane nemfuneko ye-torque.Isebenzisa amagiya ensimbi agayiwe kanye nesakhiwo sokudlulisa iplanethi, ithembekile, ayilungiswa futhi ivuselela uwoyela, iyonga isikhala.Ingasetshenziswa emikhakheni eminingi:

Umthengisi wesitolo esikhulu

Imishini yokupakisha Isihambisi sebhande

Ulayini wokuhambisa ibhandeBLD 60 Izimpawu Ze Drum Motor

Igobolondo lesigubhu

Impahla yegobolondo lesigubhu elijwayelekile iyinsimbi ethambile • Igobolondo le-garde yokudla liyinsimbi engagqwali engama-304 • Igiya legiya elijwayelekile le-cylinder rolling mill - igiya • Ukunemba kwensimbi ye-alloy ephezulu, iqinisekisa ukudluliswa komsindo ophansi uma • Ukudluliselwa kwegiya leplanethi